Questions? 800-523-5874 | [email protected]

- Prepmaster™ Specimen Preparation Robot

- TEM Grids

- TEM Window Grids

- Omniprobe Nanomanipulation Systems

- K-kit Wet "Liquid" TEM Kit

- Specimen Mounts

- SEM Specimen Holders

- Index and Finder SEM Grids

- SEM for Forensics

- SEM Sample Preparation Station Materials

- Cryogenic Personal Protection Equipment

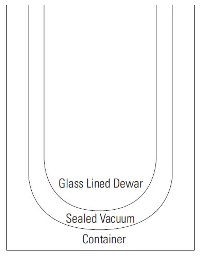

- Cryo Dewars & Flasks

- Cryogenic Grids & Accessories

- Cryogenic Vials & Racks

- Cooling Chambers & Ice Baths

- Prepmaster™ Specimen Preparation Robot

- Laboratory Microwave Ovens

- LYNX II Automated Tissue Processor

- EMS Poly III

- Microtomes

- Tissue Slicers

- Rapid Immersion Freezer

- Heaters & Chillers

- SEM Cooling Stage

- Glow Discharge Systems

- Sputter Coaters & Carbon Coaters

- Stages

- Freeze Dryers

- Critical Point Dryers

- Cryo-SEM Preparation System

- Specimen Transfer Systems

- Decontaminators

- Desiccators

- Centrifuges

- Dry Baths

- Stirrers, Hot Plates

- Vortexers & Magnetic Mixers

- Rotators & Rockers

- Ovens & Incubators

- Vibration Isolation

- Air Sampling

- Vacuum Pumps

Shallow Wide Mouth Flasks

Shallow Wide Mouth Flasks

EMS #61892-10, 61892-19

Handling ThermoFlasks

Care must be taken when using flasks. Any product used under vacuum is a potential hazard and needs to be treated with caution. Follow the safety regulations of your laboratory or institution. Specific warnings are listed below to avoid some of the more common errors.

Failure to follow proper procedures, heed warnings and cautions can result in failure of the flask with potential expelling of the contents and subsequent harm to user.

Warning

Contact of liquid nitrogen with the skin or eyes may cause serious (freezing) injury. When handling liquid gases, appropriate Personal Protection Equipment (PPE) must be worn: insulated or rubber aprons; goggles or facemasks; insulated or rubber gloves (easily removable).

Caution

Pre-cool the flask, as a potentially dangerous situation could result from pouring liquid gases into a room temperature Thermoflask. When pouring liquefied gases from one container to another, the receiving container should be cooled gradually to prevent thermal shock. Pour liquid slowly to avoid splashing. The receiving vessel should always be vented to the atmosphere and high concentrations of excess oxygen and/or nitrogen should not be allowed to collect.

Warning

Nitrogen gas can cause suffocation without warning. Store and use liquid nitrogen only in a well-ventilated place. As the liquid evaporates, the resulting gas displaces the normal air in the area. (The issuing gas is invisible. The cloudy vapor that appears when liquid nitrogen is exposed to the air is condensed moisture, not the gas itself.) In closed areas, excessive amounts of nitrogen gas reduces the concentration of oxygen and can result in asphyxiation. Nitrogen gas is colorless, odorless, and tasteless, so it cannot be detected by the human senses. Breathing an atmosphere that contains less than 19.5% oxygen can cause dizziness and quickly result in unconsciousness and death. Therefore, the use of oxygen monitoring equipment is strongly recommended.

Caution

It is recommended to have this vessel tested by a qualified cryo-vessel service technician every 7-10 years, regardless of any problems (or lack thereof) there may have been in the past. This will help ensure your samples against sudden loss of liquid nitrogen due to vacuum failure.

Warning

- All Thermoflasks in stainless steel containers have vented lids to prevent build-up of gas pressure when holding a gassing substance. The ability of the vent to release pressure should be checked periodically

- DO NOT cover any glass flask with any fixed or heavy object that might form a seal around the rim either naturally, or induced by freezing

- If liquid gases or other materials of extremely low temperatures are being used, ONLY use a stirring rod with a PTFE (polytetrafluoroethylene) or comparable form of protective coating, to mix or stir substances in the flask

Flask Capacities

| Catalog # | Capacity | Liquid Nitrogen Holding Times | Inner Diameter | Outer Diameter | Height |

| 61892-10 | 1000 ml | 38 hours | 5⅜" | 7" | 4⅛" |

| 61892-19 | 1900 ml | 48 hours | 6" | 7¼" | 5½" |

Note

- Holding times are intended as a guide only, to illustrate the probable time it takes for a lidded, stainless steel flask to empty completely after being filled with liquid nitrogen.

- The times may change depending on

- Higher or lower ambient temperatures

- Whether or not the lid is removed for examination of the contents

- The mass of the material being frozen

- Flasks may be almost empty of liquid nitrogen but they will continue to be effective storage vessels for frozen material because the contents will be held in the vapor phase of the nitrogen, i.e. the liquid nitrogen will have boiled to become a very low temperature gas. This can benefit users who wish to store materials in a frozen state, but not at the exceptionally low temperature of the liquid nitrogen itself.

Operation

- Carefully inspect vessel. Check for signs of damage such as scratches, chips or discoloration of glass. DO NOT use if any damage is found!

- It is advisable to fill all new units with liquid nitrogen and watch liquid nitrogen loss rate for a few days.

- Use a wooden yardstick to measure liquid nitrogen level. Level will be indicated by frost line which develops when dipstick is removed and waved in a back and forth motion away from the user.

- To avoid damage to cryogenic storage vessel which may result in premature vacuum loss, it is important that the following procedure be used during the addition of liquid nitrogen to a warm vessel:

- Caution! Never overfill liquid nitrogen vessels.

Add only a small amount of liquid nitrogen (10% of unit volume) to new or warm vessels.

Add only a small amount of liquid nitrogen (10% of unit volume) to new or warm vessels.- Allow this small amount of liquid nitrogen to sit in the covered vessel for a minimum of 2 hours. This will limit stress caused by the sudden temperature change associated with adding liquid nitrogen to a warm vessel.

- Add an additional 20% of unit volume of LN2 to vessel.

- Allow vessel to sit for 48 hours and monitor liquid nitrogen consumption.

- Fill vessel as desired. Remember to allow for displacement of liquid nitrogen when canisters and canes are inserted.

- Insert and remove samples slowly. Allow liquid nitrogen to run out of samples.

Product Information