Questions? 800-523-5874 | [email protected]

- Prepmaster™ Specimen Preparation Robot

- TEM Grids

- TEM Window Grids

- Omniprobe Nanomanipulation Systems

- K-kit Wet "Liquid" TEM Kit

- Specimen Mounts

- SEM Specimen Holders

- Index and Finder SEM Grids

- SEM for Forensics

- SEM Sample Preparation Station Materials

- Cryogenic Personal Protection Equipment

- Cryo Dewars & Flasks

- Cryogenic Grids & Accessories

- Cryogenic Vials & Racks

- Cooling Chambers & Ice Baths

- Prepmaster™ Specimen Preparation Robot

- Laboratory Microwave Ovens

- LYNX II Automated Tissue Processor

- EMS Poly III

- Microtomes

- Tissue Slicers

- Rapid Immersion Freezer

- Heaters & Chillers

- SEM Cooling Stage

- Glow Discharge Systems

- Sputter Coaters & Carbon Coaters

- Stages

- Freeze Dryers

- Critical Point Dryers

- Cryo-SEM Preparation System

- Specimen Transfer Systems

- Decontaminators

- Desiccators

- Centrifuges

- Dry Baths

- Stirrers, Hot Plates

- Vortexers & Magnetic Mixers

- Rotators & Rockers

- Ovens & Incubators

- Vibration Isolation

- Air Sampling

- Vacuum Pumps

Graphene Oxide Membranes: A Scalable and Efficient Application of 2D Materials

Graphene Oxide Membranes: A Scalable and Efficient Application of 2D Materials

EMS Catalog #GOHC300Cu10 to GOQ400R1213Cu100

|

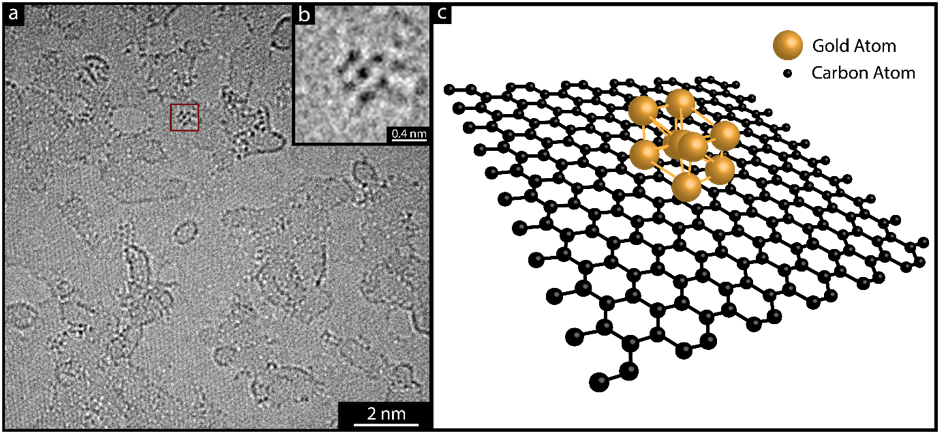

| a) A high-resolution TEM image showing gold nanoparticles dispersed across modified graphene-oxide. b) Magnified image of red-box area in image a, showing single gold-nanoparticles with atomic rsolution. c) Schematic depicting of image b in 3D. Adapted from Bosch-Navarro |

Since the first report on producing the two-dimensional (2D) material graphene in 2004, there has been considerable time and money invested into developing new graphene-based technologies. These aim to exploit the remarkable properties of graphene including its strength and electrical- and thermal- conductivity. At a basic level, transmission electron microscopy (TEM) image contrast is caused by the scattering of electrons and is dependent on the thickness and composition of the sample material. The ultimate thinness of graphene, combined with the low atomic number of carbon, provides the ideal blueprint for a low-contrast TEM support. Producing graphene and transferring onto a TEM support grid is difficult to carry out at large scale and high yield. A simpler, cheaper, and higher yield production method uses graphene oxide, a 2D material similar to graphene. Graphite is reduced using a strong oxidising agent, and the oxygen functionalities introduced render it hydrophilic, allowing it to be easily dispersed in water, as well as other organic solvents. Controlled sonication of the water-dispersed material allows finely-tuned exfoliation of the graphene oxide, which in turn allows samples, including TEM supports, to be coated in single or few-layer graphene oxide. These flakes possess the low contrast benefits of graphene, which, combined with the efficient production of graphene oxide, make it ideal as a cheap, high-yield TEM support.